About Arkansas Tornado Shelters

World Class Manufacturing

Granger Industries has a long reputation of high quality, superb manufacturing capability and far exceeding expectations in rotational molding and manufacturing. With roots to John Grimes Sr. who was one of the "founding fathers" of Rotational Molding in the United States, the company’s foundation was based on his experience. His son, also John Grimes founded Granger Industries, Inc. in 1994. A 40 year pioneer himself the Grimes family’s influence was integral thru the history of Rotational Molding and Granger Industries has followed closely this reputation.

John and his original partners started the company in Sharonville, OH but quickly outgrew that location within 2 years. In 1996, finding a move essential for continued growth; John and his business partner chose another Cincinnati-Dayton area suburb of Middletown, OH. This move also prompted John to start branching Granger Plastics into new opportunities that developed into long term relationships integral to the direction of the company.

By the autumn of 1998 they found themselves again in need of additional expansion. Large capital investments in machinery and equipment were made boosting the rotational molding capabilities and allowing Granger to manufacture larger parts. It was also at that time that John and his partners required additional skills for the more extensive opportunities, so they added one more member to the team.

By the autumn of 1998 the firm was again in need of expansion to it’s maximize ability and capacities. Large capital additions in machinery and equipment were made boosting its rotational molding capabilities. It was also at that time that John and his partners required additional skills for the more extensive opportunities, so they added one more member to the team. The new partner was Jim Cravens, a strongly pursued associate of Mr. Grimes' past in rotational molding. Jim was brought in during a significant duration of adjustment. A Mechanical Engineer by education and profession, Jim has over 25 years of experience in steel fabrications. Much of his experience was acquired during his tenure of design & making, research, development and production in the commercial lawn mower industry. He additionally delivers virtually twenty years of rotational molding experience to complement his vast understanding of steels and metal fabrications. The combination of knowledge and experience was the perfect match for Granger’s needs. As possibilities originated from several new directions Granger continued its growth.

The new partner was Jim Cravens, a long time associate of Mr. Grimes' past in rotational molding. Jim was brought in during a significant period of change. A Mechanical Engineer by education and profession, Jim has over 25 years of experience in steel fabrications. Much of his experience was acquired during his tenure of design, manufacturing, research, development and production in the commercial lawn mower industry. He additionally delivered almost twenty years of rotational molding experience to complement his vast understanding of steels and metal fabrications. This valuable combination of experience and education was the perfect match for Granger’s specific needs.

As Granger Industries continued to grow it began to broaden its scope in to a wide-ranging number of industries, OEMS and products to expand its manufacturing reach. It became necessary to continue this expansion through additional areas over the last few years.

Granger has yet again made several major renovations including boosting warehousing capacities to house more material to maximize gain from competitive material prices, as well as adding significant equipment to aide in its in-house fabrications and repairs. These improvements all help bring the most competitive pricing for clients. Granger has additionally made excellent strides in collaborating with pigment manufacturers and creating effects by utilizing additives to create custom colors. These pursuits allow the business to stay front and center of rotational molding material advancements. Granger continues to move ahead in the plastics industry by providing industry leading propriatery products such as the Granger ISS Tornado Shelter and the Sandsaver™ Beach Erosion barrier. Its latest product additions include ForeverSafe Products, a line of theft deterrent cemetery products as well as the launch of Granger Aerospace Products and the substantial expansion into the air cargo and aerospace industry. These innovations are the backbone of a company that continues to lead in its respective induatry.

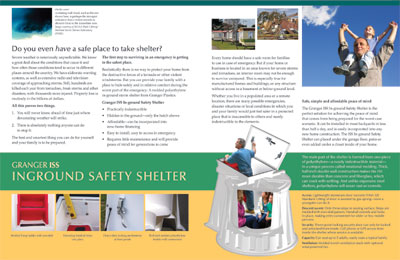

A Long History of Shelter Manufacturing

Granger Plastics Company is a full service custom rotational molder able to carry a project completely from design to manufacturing and beyond. The company has a lengthy history making storm shelters via its custom manufacturing. This experience began soon after the firm was founded. Through the many years of making shelters Granger has had the ability to recognize some typical concerns customers voiced regarding the design and installation specifics of other tornado shelters. It was this forst hand experience with consumer concerns that led Granger to design and manufacture its own shelter, the Granger ISS, to deal with the typical problems seen with this type of item.

This foundation of manufacturing experience was the inspiration of the initial design of the Granger ISS which resolved several issues seen in the previous decade of manufacturing shelters for other businesses. Branching off into the exclusive style of the Granger ISS has actually allowed the improvements to proceed throughout the development of this item. Unlike the typical storm shelter manufacturer the innovations and improvements to the Granger ISS have continued to be implemented.

Commitment to Continuing Storm Shelter Development

Potential tornado shelter customers voiced concern with installation specifications and requirements of various storm shelters throughout Grangers 20 years history of Tornado shelter production. This problem was the premise for the reversed taper design which allowed for installation without any additional anchoring. The door was developed to be level with the ground rather than partially out of the ground or at an angle which was another repeated request from customers. These two innovations were the initial improvements the Granger ISS tackled yet there would be many more to follow.

From that success Granger continued to establish a more secure, easier and additionally aesthetically pleasing unit. Granger has developed a 3rd generation door, which offers the same durable rotational molding construction as the body of the tornado shelter unit. This door, as the previous generations, was tested at Texas Tech University's Wind Science and Engineering research center to meet or exceed FEMA 320 & FEMA 361 debris impact standards. The present door model comes standard with a dual shock system for the easiest door entrance and exit. The door is also available in customized colors permitting consumers to reduce the appearance of the unit or coordinate with house shades or landscape design ideas. . The three step molded entry with locking handrails was also a consideration in the original design. Granger has also developed the non skid surface area of the entry and includes a led lighting system for increased safety when entering the shelter. Finally the newest development of foam filling the unit not only drastically increases convenience of installation, but also additionally battles condensation. Innovation is an important part of Granger's production philosophy and the advancement of the Granger ISS is an outstanding example of that commitment.